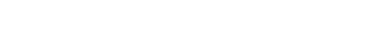

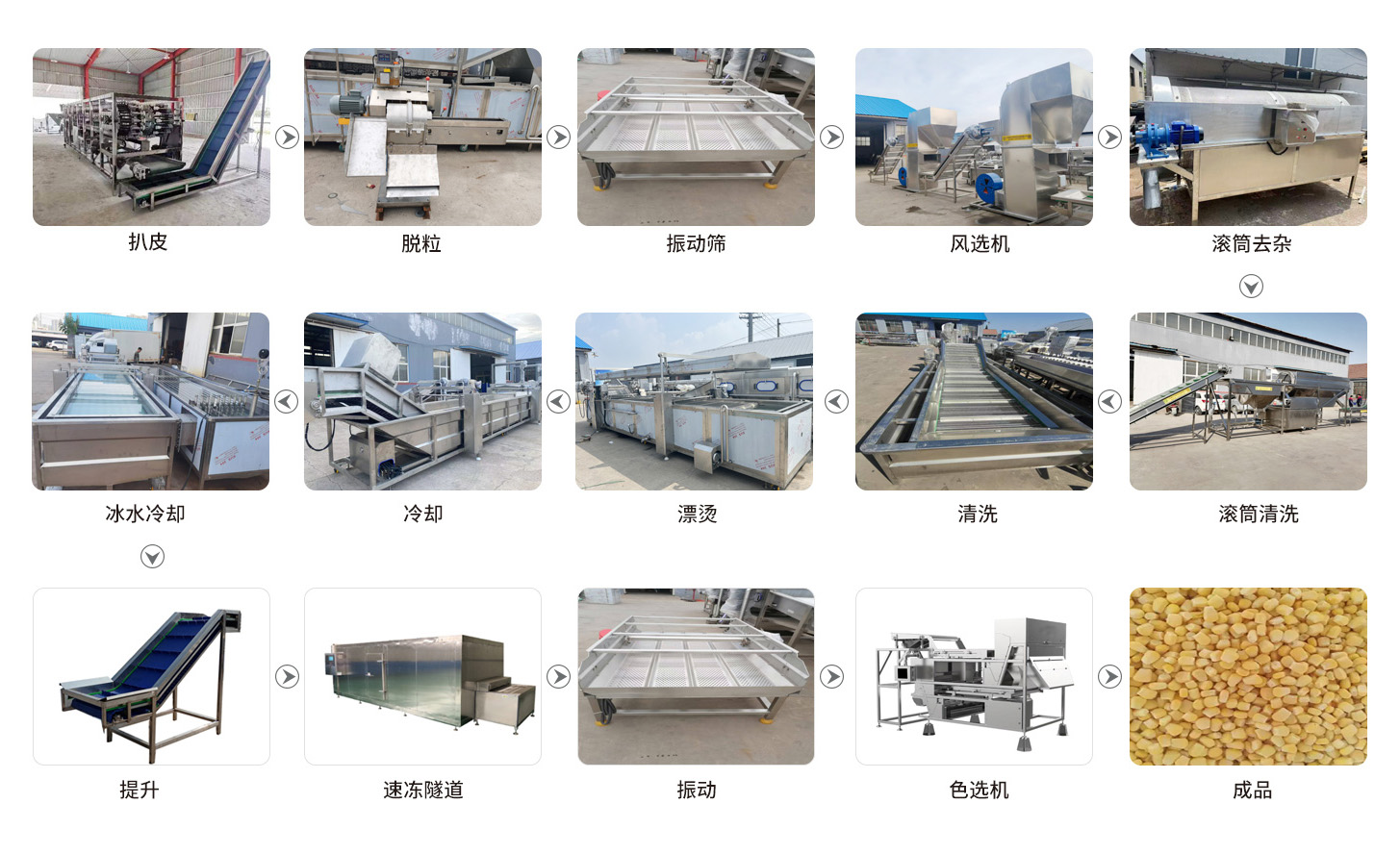

Equipment Introduction:

The complete set of corn kernel processing equipment is an automated production line that integrates multiple processing steps, mainly including pre-treatment equipment, freezing equipment, post-treatment equipment, and supporting refrigeration systems.

Peeling machine: used to remove the outer skin of corn, can choose large or small equipment according to the yield. The design of the peeling machine usually takes into account the characteristics and processing efficiency of corn, ensuring that the corn kernels are not damaged while removing the outer skin.

Cleaning machine: Clean the peeled corn to remove surface impurities, whiskers, insects, hair, etc. The cleaning machine is equipped with a bubble generation device, which utilizes the principle of water's mutual impact to make the corn kernels roll up, down, left, and right, achieving the purpose of cleaning. At the same time, the equipment is also equipped with hair removal, whisker removal devices, and spray devices to ensure cleaning effectiveness.

Head and tail cutting machine: Cut the cleaned corn into appropriate particle sizes to meet different market demands. The blades of a cutting machine are usually made of materials to ensure cutting effectiveness and service life.

Steaming machine: Process corn until 7-8% cooked, and choose a water boiling machine or steam steaming machine according to the process. The design of the steaming machine takes into account heating uniformity and temperature control, ensuring that corn maintains good taste and nutritional value during the steaming process.

Cooling machine: Cool the steamed corn to a suitable temperature for quick freezing in the next step. The design of the cooling machine takes into account cooling speed and temperature control, ensuring that corn does not lose its taste and nutritional value during the cooling process.

Quick freezing machine: for rapid freezing of corn kernels, commonly used ones include fluidized freezing machines, tunnel freezing machines, etc. The quick freezing machine can quickly lower the temperature of corn kernels to below -18 ℃, locking in the nutrition and flavor of corn. The tunnel type quick freezing machine adopts a mesh belt conveyor, which is suitable for assembly line processing and production mode. It has a high degree of automation, saves labor, is safe and durable, easy to operate, and is easy to install and maintain.

-

Electric heating deep fryerAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Electric heating deep fryerAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More -

Fried round potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Fried round potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More -

Fried assembly lineThis production line is equipped with an automatic oil temperature control systemView More

Fried assembly lineThis production line is equipped with an automatic oil temperature control systemView More -

Fried square potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Fried square potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More